A Film Galvanising System With Cathodic Protection

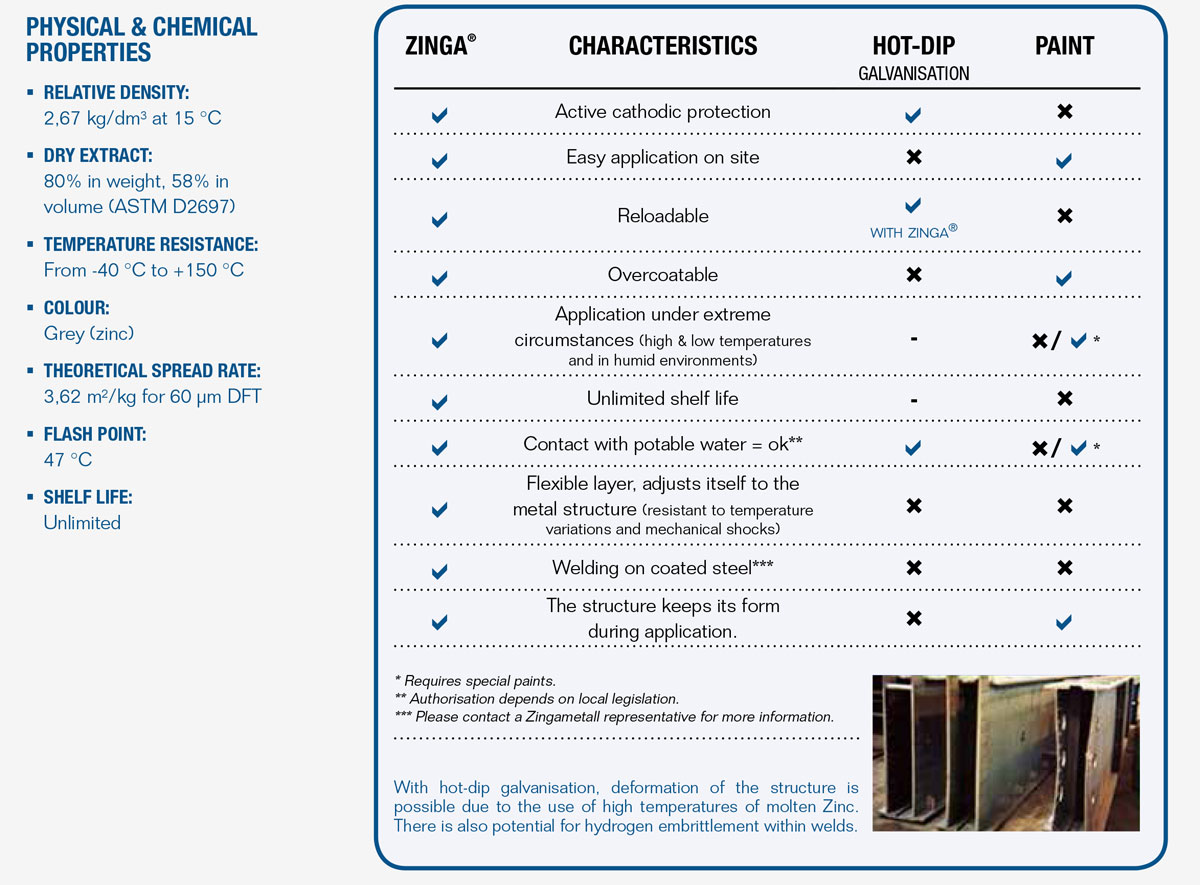

Every year corrosion is costing billions to the industry. This corrosion doesn’t merely make the assets appear neglected, more importantly it causes structural instability and consequently poses a serious safety hazard. It also causes severe disruption of the production process and thus profitability. ZINGA® differentiates from other anti-corrosion methods in combining both Passive and Active protection in an easily applied film galvanising system that not only delivers active cathodic protection but also provides a passive physical shield.

EXTREME ENVIRONMENTS DEMAND

SUPERIOR PROTECTIOIN

WHAT IS ZINGA®?

ZINGA® is a one component Film Galvanising System containing 96% zinc (dust) in its dry film. It is a metallic coating and not a paint. The purity of the zinc used, is so high that dry ZINGA® does not contain any toxic elements.

ACTIVE AND PASSIVE PROTECTION

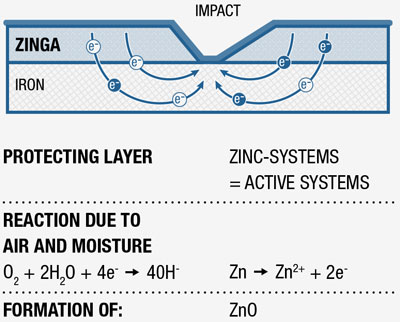

ACTIVE GALVANIC PROTECTION

The zinc in ZINGA® (anode) sacrifices itself, protecting the steel beneath in a comparable and even better way than hot-dip galvanising. Upon impact, the electron flow resulting from a potential difference between the Zinc and steel will prevent the steel from corroding.

GALVANIC – NO CORROSIO

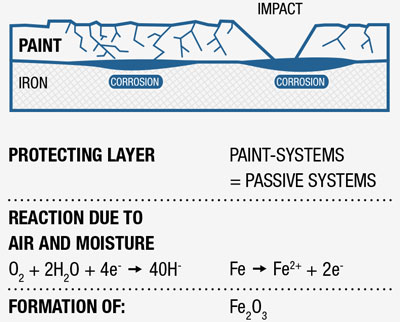

PASSIVE BARRIER PROTECTION

As the ZINGA® oxidises, a layer of zinc salts slowly builds up on the ZINGA® surface, closing the film and enhancing the barrier effect of the coating. Next to this, a supplementary barrier protection is provided by the binder in ZINGA®. The binder reduces the depletion of the Zinc, providing a long lasting active protection.

NON GALVANIC – CORROSION

ZINGA®

IN ZINC WE TRUST FOR FIGHTING RUST

HOW CAN IT BE USED?

STAND ALONE SYSTEM

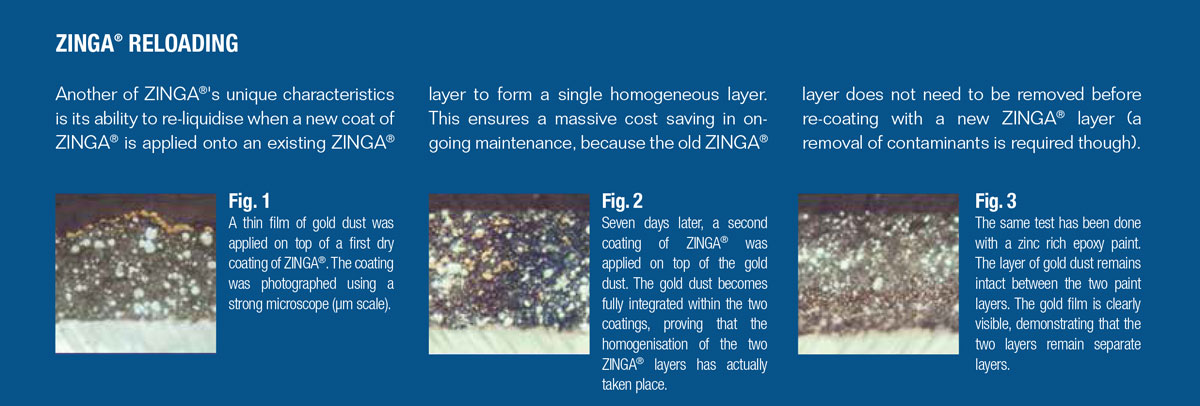

ZINGA® provides comparable protection to conventional galvanising without the need for topcoats. Although ZINGA® is only available in grey (the natural colour of zinc), the significant advantage of this form of application is that the ZINGA® layer can be re-coated at any point in the future with the bare minimum of preparation and without compromising the integrity of the coating (see Re-charging of ZINGA®). ZINGA® on its own is often used, because the structure is already on site or too big for the molten zinc baths. For optimal protection, ZINGA® should be applied in two layers of 60 or 90 µm DFT each.

AS A PRIMER WITH SUITABLE TOPCOATS

AS SHOP PRIMER

REPAIR FOR WORN OR DAMAGED HOT-DIP GALVANISING OR HOT METAL SPRAY

ON REBARS

HOW TO APPLY ZINGA®?

Once thoroughly mixed, ZINGA® can be applied by using a normal paintbrush, a short-fibre roller (not for the first coat), or a conventional or airless spray-gun. When applying ZINGA® by spraying it must only be thinned with Zingasolv.

ZINGA® can be applied in a wide variety of weather conditions. The application surface temperature range is from -15 °C to +60 °C, where conditions allow with a maximum humidity of 95% so long as the steel temperature is 3 °C above the dew point. Like all coatings the substrate surface should be free from all types of contamination.

PREPARATION OF THE SURFACE

NEW METAL SURFACES:

Steam-clean or high-pressure wash-down all surfaces, followed by a grit or slurry blasting to SA 2.5 to obtain a roughness degree Rz 50 to 70.

OLD, PREVIOUSLY GALVANISED, PAINTED AND / OR RUSTY SURFACES:

Steam-clean to remove all contamination from porous surfaces. Allow to dry off and blast-clean as normal.

GALVANISED AND ZINGANISED STEEL IN (FAIRLY) GOOD CONDITION:

Steam-clean the surface, followed by a light sweep blast to remove the zinc salt layer.

DRYING TIME

ZINGA® is touch dry and dust-free in about 10 minutes at 20 °C (40 µm DFT). It can be overcoated with a new layer of ZINGA® 1 hour after touch dry. ZINGA® can be overcoated with a compatible paint after 6 to 24 hours, depending on drying conditions. To overcoat ZINGA®, use a mist/full coat technique.

INDEPENDENT TEST RESULTS

Over the last 30 years ZINGA® has undergone numerous testing at different certified laboratories all over the world. All testing was according to local and international standards.

The most important include:

- ISO 12944: ZINGA® 2 x 90 µm DFT – C5 I/M High

- NORSOK M-501- syst. 1 and 7: ZINGA® 2 x 60 µm DFT – passed

- ASTM B-117 (Salt spray): ZINGA® 2 x 90 µm DFT – over 4200 hours passed

CERTIFICATIONS AND APPROVAL

In consequence of ZINGA®’s performance (proven by testing), ZINGA® has been approved for use by governments, companies, armies. The most important include:

- Lloyd’s Register (Approval for use in void spaces)

- European Technical Approval (Europe)

- Approval by APAS (Australia)

- Registration by Petrobras (Brazil)

- Approval by Ministry of Transport (Canada)

- Approval by Czech Railway (Czech Republic)

- Approval by GASCO (Egypt)

- Approval by Engineers India Limited (India)

- Approval by Statoil (Norway)

- Approval by CFE (Mexico)

- Approval by Meralco (Philippines)

- Approval by Agrement Technic (Romania)

- Approval by SWCC (Saudi Arabia)

- Approval by Land Rover (UK)

- Approval by Crown’s Castle (USA)

Office

Call Us

(+95) 9 - 7924 82739

(+95) 9 - 765458228

Contact

admin@royalmarinegroup.com